Floating roof tanks are commonly protected against lightning ignition by bonding the floating roof to the seal shoes at no less than 3m 10ft intervals use of insulating sections in the hanging linkages covering sharp points on hangers with insulating materials and installation of electrical bond straps across each pinned hanger joint.

Supporting a floating roof tank.

Advance tank can evaluate the existing tank s design and determine what modifications need to be made to support a floating roof.

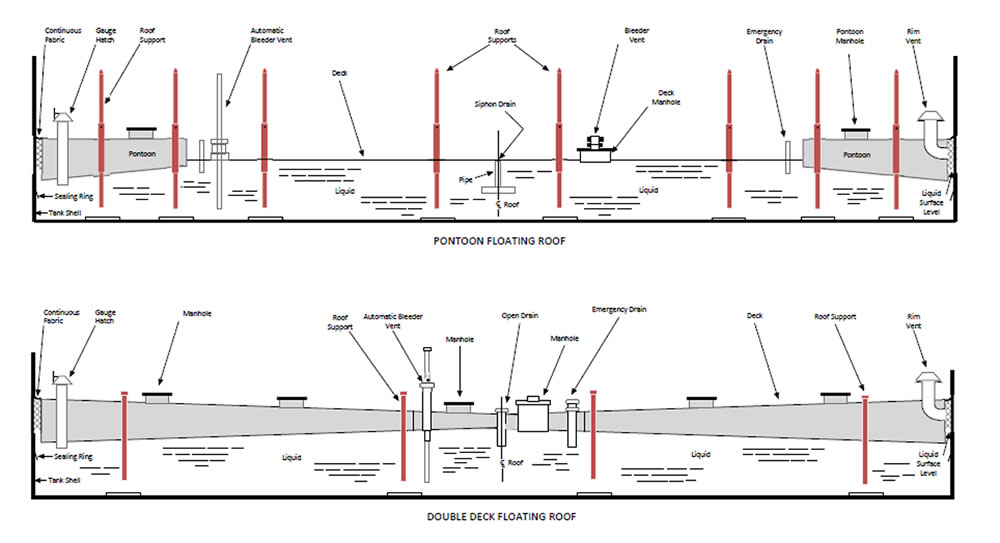

Summary floating roof supports are designed very similar to fixed roof columns.

Failures of floating roof primary and secondary seals foam filled or liquid filled have been a significant concern.

The length of the legs must be adjustable from the top of the roof and the legs must be notched or perforated at the bottom to provide drainage.

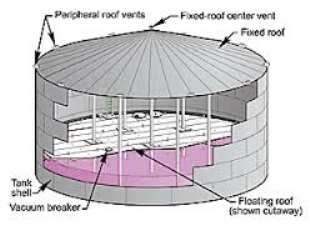

We can take your cone roof tank and modify it to a floating roof for your changing work environment.

Fixed roof collapse is virtually non existent because the fixed roof s attachment to the shell limits any movement at the top of the columns.

The floating roof must be provided with landing legs that are designed to support the external floating roof under a uniform design load of at least 25 psf api.

External floating roof is the most suitable for large crude oil storage tank form 20 000m 30 000m 50 000m to 100 000m etc.

If floating roofs are similarly restrained against this movement they will be highly reliable.

Poor tank turnaround practices with inadequate checking of roof supports.

Once this is done our crews can retrofit your tank with a new floating roof.

There was a fatality on a large diameter floating roof tank when a contractor died under the weight of the roof plates which collapsed on him.