These assemblies are created by eliminating ventilation openings and moving the thermal moisture and air control boundaries to the plane of the roof deck.

Unvented attic ceiling assembly.

However architects of these compact roof assemblies must consider vapor permeance and arrangement of the materials to produce acceptable hygrothermal performance and low risk of condensation in the resulting conditioned attic space.

This document provides a brief description of different types of unvented roof assemblies and the benefits of unvented roof construction.

Low slope and steep slope unvented roof systems i e.

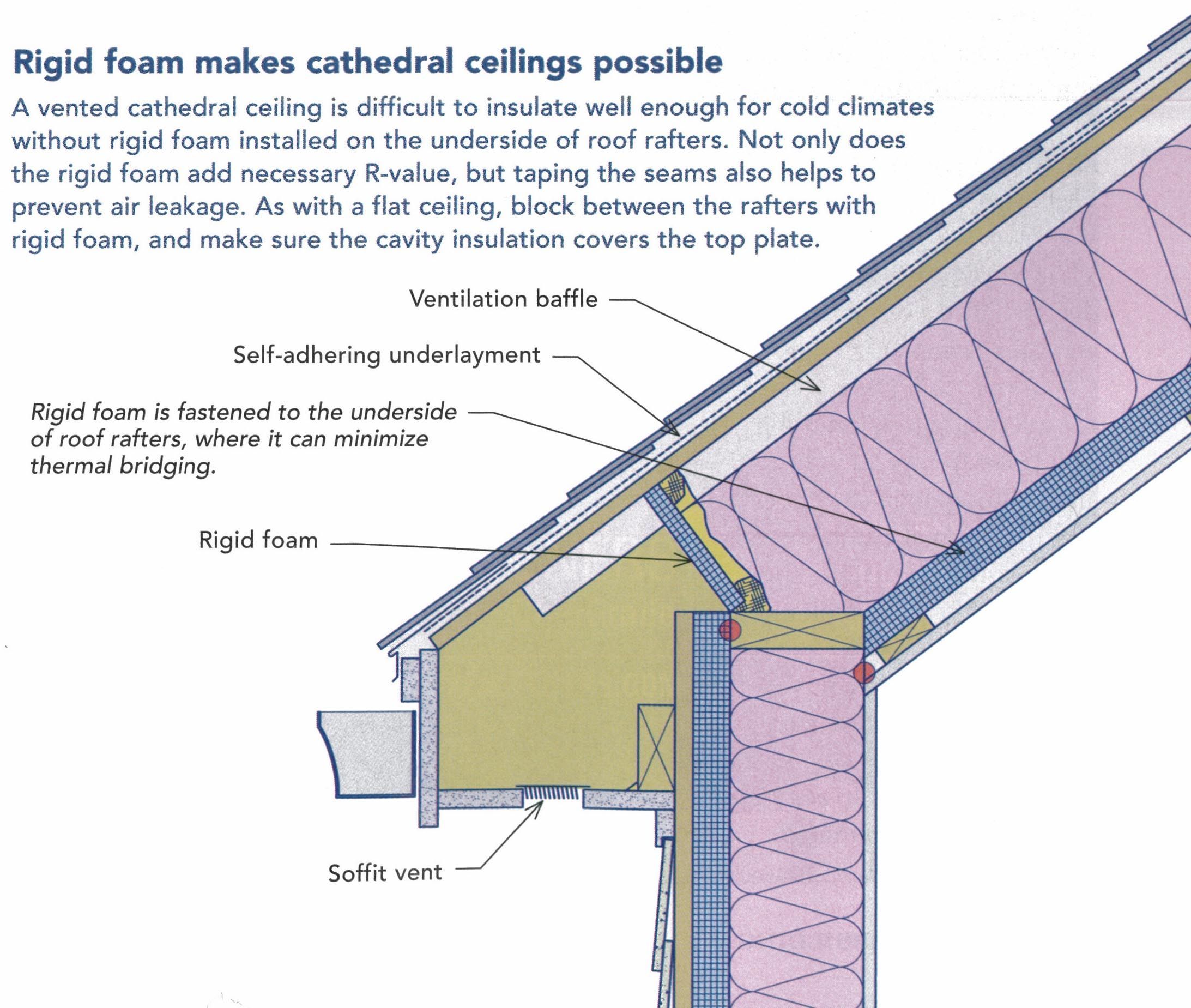

You can install all of the insulation above the roof sheathing but the foam has to be thick enough to meet minimum code requirements for ceiling r value.

Four options for building an unvented roof assembly.

Unvented roof assemblies such as conditioned attics and unvented cathedral ceilings are becoming common in north american construction.

Poorly insulated ducting can cause heat loss in colder months and the loss of conditioned air in the summer in vented attics.

Install insulation along the underside of the roof deck of an unvented attic rather than on the ceiling deck of a vented attic for either of two reasons.

Rigid foam above roof sheathing.

Unventilated attics are common where roof assemblies are complex and it s difficult to create a sealed ceiling plane.

Insulation and air barrier are applied directly to the underside of the roof deck are common in applications where designers are seeking cost effective and energy efficient roof assemblies.

No interior vapor retarders are installed on the ceiling side attic floor of the unvented attic assembly 2009 irc.

The key to creating an unvented roof assembly is to keep the roof deck the principle condensing surface in roof assemblies sufficiently warm throughout the year such that condensation will not occur or to prevent interior moisture laden air from accessing the roof deck.

To provide an unvented conditioned space for locating hvac equipment in the attic and or to provide a continuous thermal barrier for designs that have complex coffered ceiling planes and or numerous penetrations for lights speakers vents soffits etc which make it difficult to achieve an airtight ceiling plane.

The rigid foam will be fairly thick see sidebar how much insulation.

The requirement that there be no vapor retarder on the interior ceiling of the unvented attic assembly is primarily intended to avoid trapping warm moist air in the attic area in warm humid climates not an issue in washington but also to make it clear that a vapor retarder is not needed at the ceiling level for the unvented attic assembly application anywhere exceptions 5a and 5c will be used for spray foam application directly to the underside of the roof sheathing.

No interior class i vapor retarders are installed on the ceiling side attic floor of the unvented attic assembly 2012 irc 3.

In an unvented attic penetrations through the ceiling directly below the attic do not need to be air sealed.