In sheet metal industry the initial estimation of formability is usually based on total elongation measured from the tensile test.

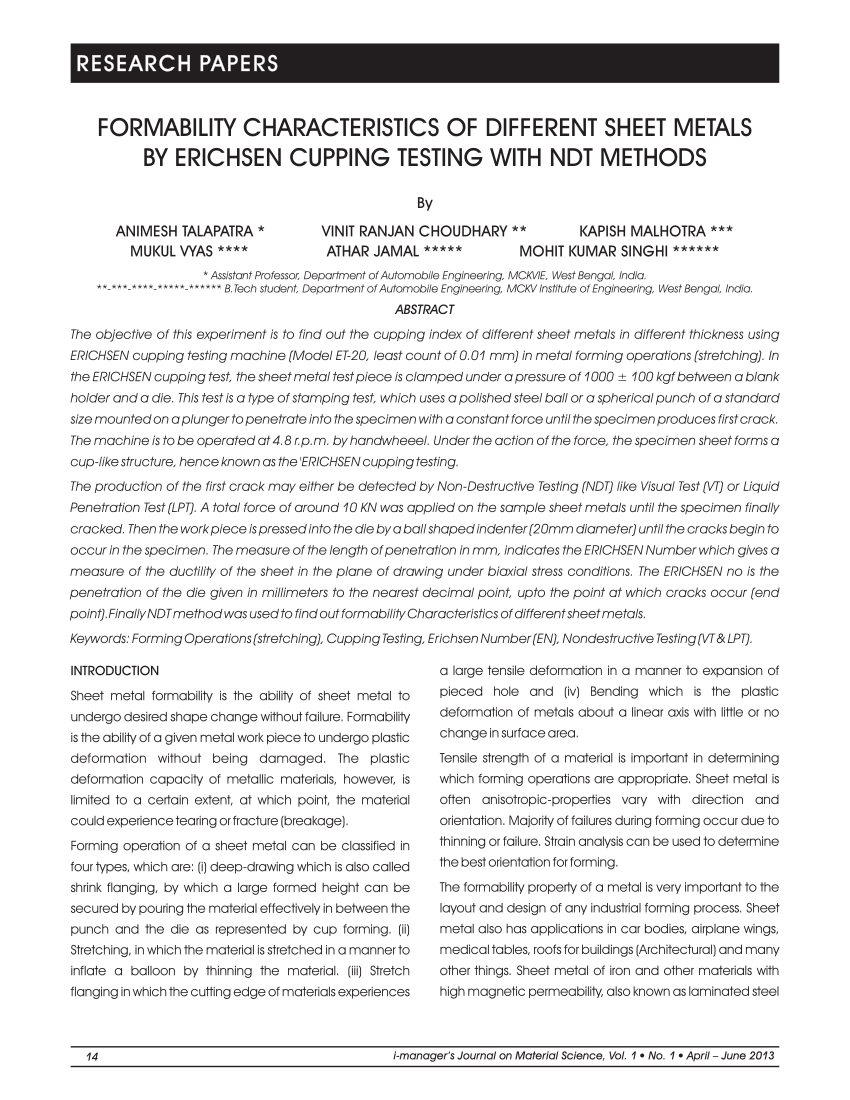

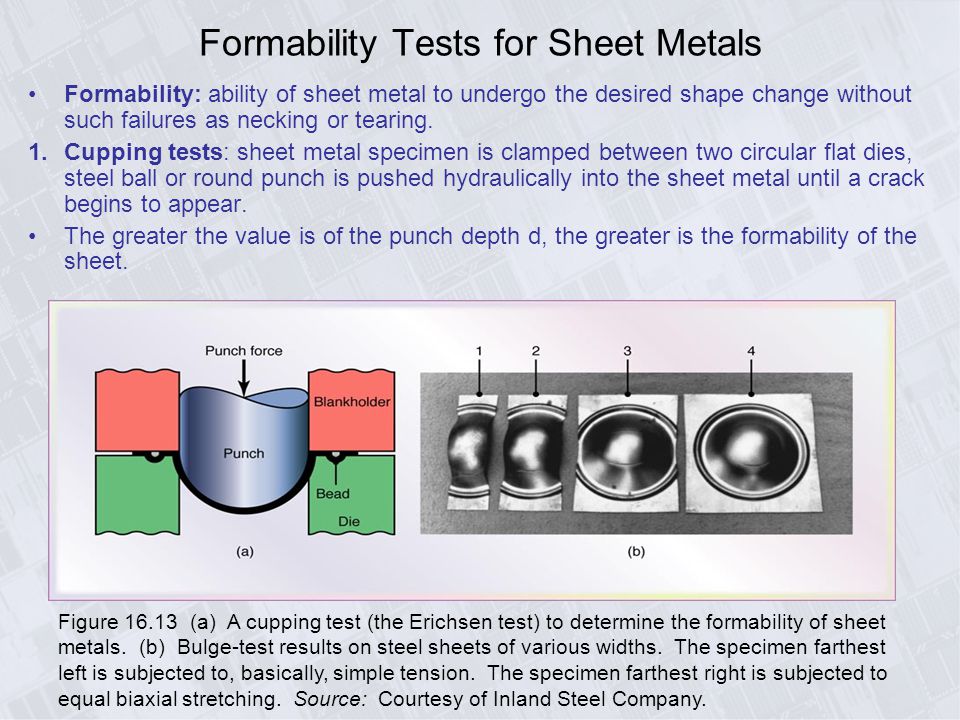

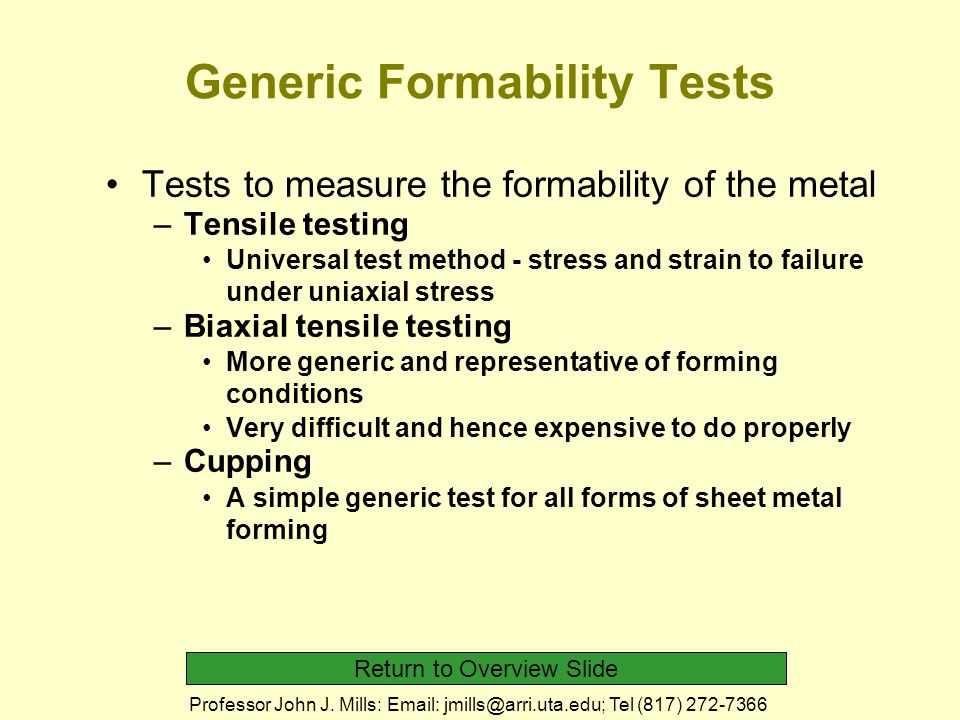

Test methods for formability of sheet metal.

The old saying garbage in garbage out rings true in this regard.

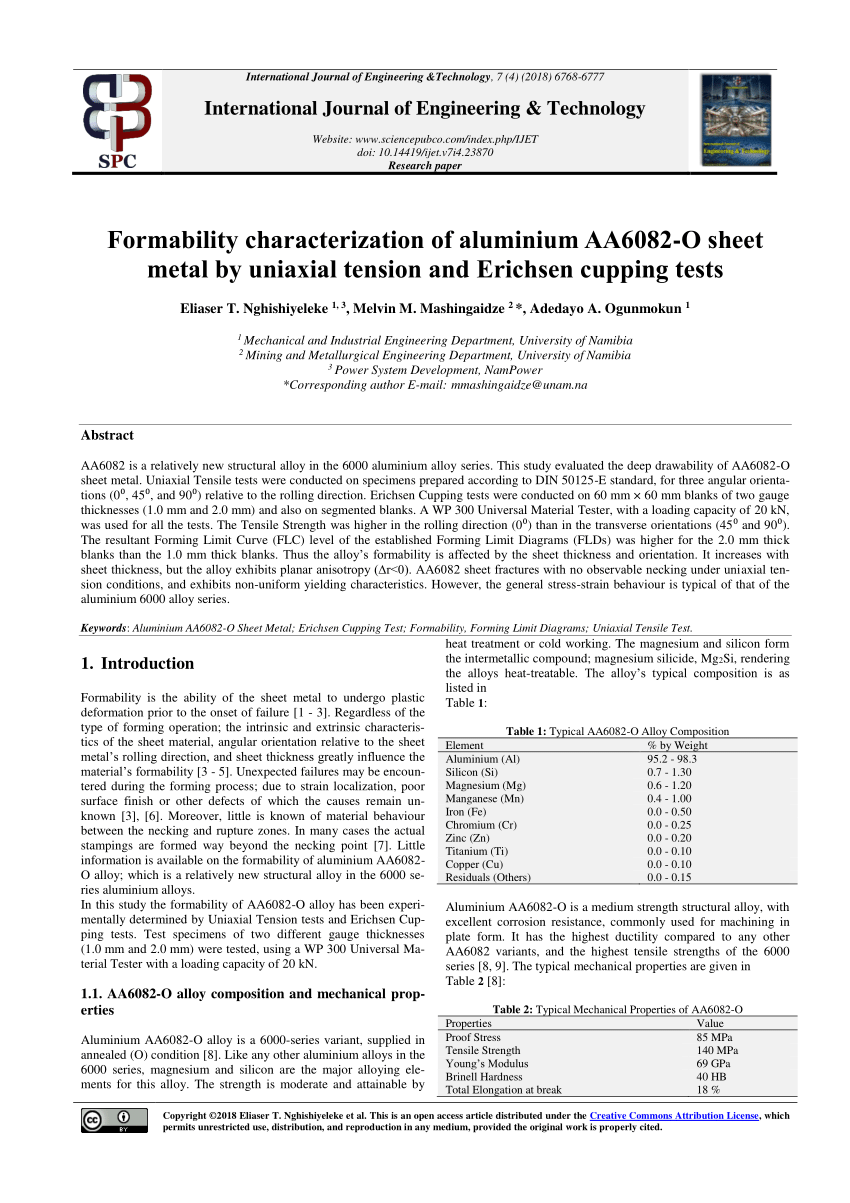

Anisotropy in sheet metal can be useful in deep drawing and other forming processes.

Astm e517 standard test method for plastic strain ratio r for sheet metal decides its determination.

It is assumed or considered that the larger is the value of total elongation the more formable is the material.

The r value of sheet varies with the applied axial strain and as such should be reported at the tested strain level unlike many other materials with r values that stay constant over the range of plastic strains.

Astm e646 stan dard test method for tensile strain hardening exponents of metallic sheet materials governs the determination of the strain hardening exponent.

This inexpensive and simple way of evaluating formability however is not very reliable because while.

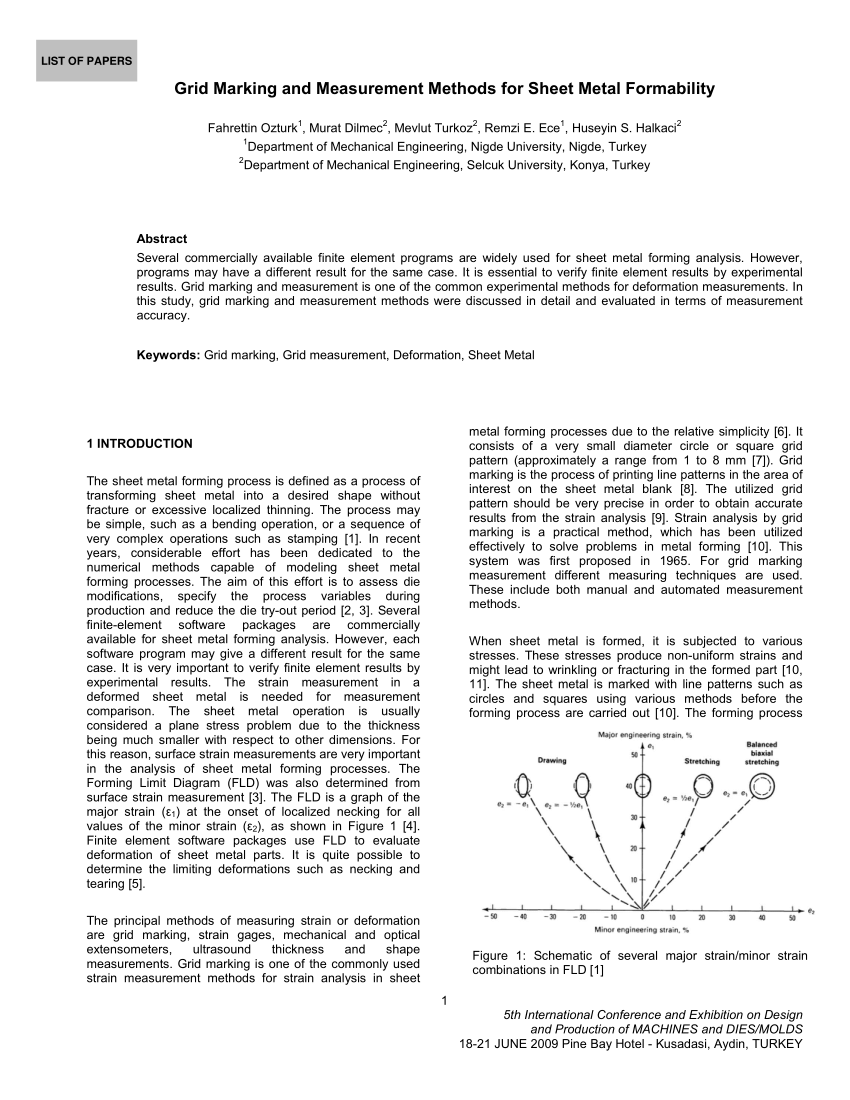

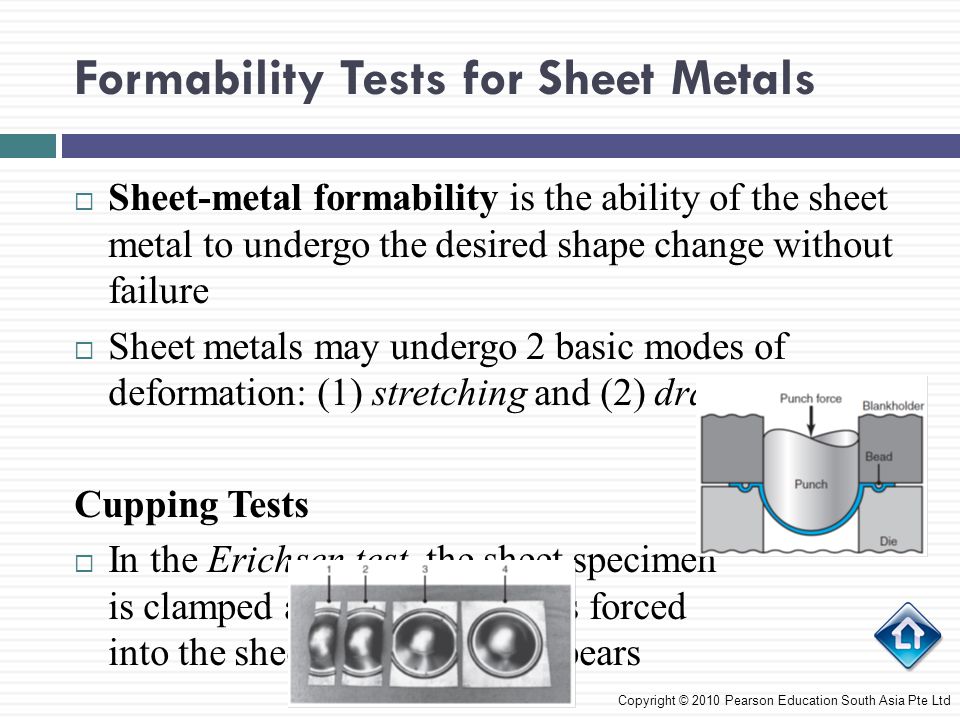

In this chapter 1 sheet metal formability tests such as the tensile test the plane strain test and the in plane stretching test are analyzed.

Tips for sheet metal testing.

Sheet metal forming simulation is almost meaningless without accurate material data.

To correctly and accurately capture the mechanical properties of material for use in simulation a tensile test is performed.

Anisotropy in sheet metals.